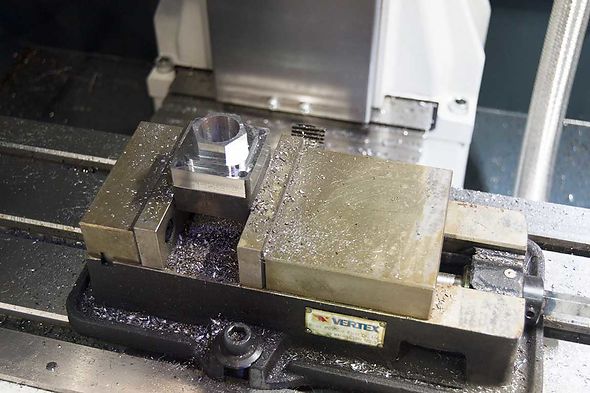

The Mini Mill 4 is a compact and versatile vertical CNC machining center that includes Fagor 8055 numerical control, linear guides, rigid threading, automatic and centralized greasing, electronic handwheel or RS-232 output among others. It provides the client with high production at a very low cost. It is a compact machine tool for work in all types of materials. The ideal option for small spaces, grouping all the possible power in a fully compact CNC machine.

Technical Characteristics

| Numerical control | ||

| Model | Fagor 8055 | |

|---|---|---|

| Worktable | ||

| Surface | 810 x 250 mm. | |

| Number of slots and measures | 3 - 16 x 53 mm. | |

| Maximum load over table | 80 Kgs. | |

| Travels & distances | ||

| Longitudinal travel - X axis | 390 mm. | |

| Transversal travel - Y axis | 240 mm. | |

| Vertical travel - Z axis | 400 mm. | |

| Distance from spindle nose to table | 75 - 475 mm. | |

| Distance from spindle center to column | 260 mm. | |

| Headstock | ||

| Spindle taper | BT-40 | |

| Tool holding system: | Pneumatic | |

| Speed range | 10.000 rpm. | |

| Power | ||

| Main motor (Inter./Cont.) | 7 / 5 HP | |

| Coolant pump motor | 0,125 HP | |

| Feedrates | ||

| Rapid feeds - X, Y, Z axis | 15 m/min. | |

| Machining feedrates - X, Y, Z axis | 10 m/min. | |

| Tool changer | ||

| Number of tools: | 8 | |

| Type | Umbrella | |

| Tool diameter | 80 mm. | |

| Tool length | 260 mm. | |

| Maximum tool weight | 7 Kgs. | |

| Weight & dimensions | ||

| Weight | 1320 Kg. | |

| Dimensions (L x W x H) | 1960 x 2115 x 2300 mm. | |

| Brand: | Travis | |